Differential Case Balancing System

Differential case balancing - with precise contour milling units

The differential case balancing systems from the CEMB - Hofmann range are available as 1- and 2-level (static/dynamic measuring) versions as well as in different configurations and degrees of automation.

From the semi-automatic through to the 4-station system, each of these systems measures the imbalance, performs the mass correction by means of precise contour milling units in combination with a CNC indexing table and checks whether the tolerance has been achieved. In the fully automatic systems of differential case balancing the cases are fed in and discharged by a revolving swivel transfer unit.

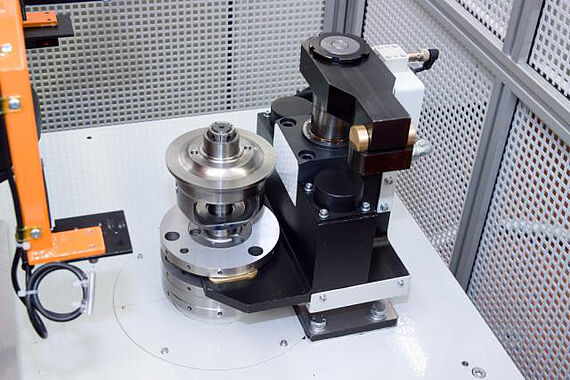

1-Station differential case balancing systems

The mass correction in two levels is performed by a 2-axis milling unit; a CNC indexing table is used to control the milling angle.

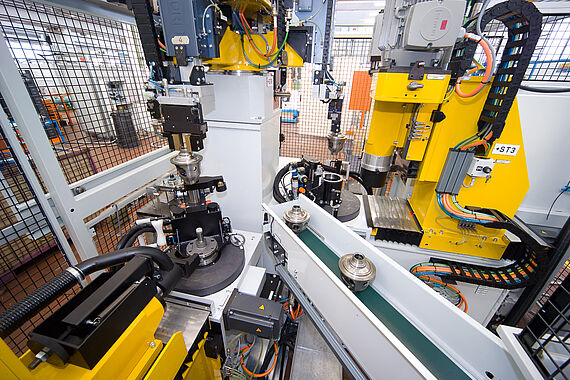

4-Station differential case balancing systems

4-station balancing machine for measuring the unbalance in 2 planes with body and flange-side mass correction by means of milling and with NC axes for a set-up-free type change.

The four stations of our system for differential cases balancing are in detail:

Station 1: Measuring stand

Station 2: Compensation top level by contour milling

Station 3: Compensation bottom level by contour milling and control run

Station 4: Part transfer

A 4 x 90° revolving swivel transfer unit allows simultaneous loading and unloading as well as part transport between the individual stations.

Your competent contact for Balancing Technology

Balancing Technology

Christian Rubiu

+49 6242 904-115

balancing@hofmannmaschinen.com

If our offer of an automatic differential case balancing systems is of interest, please use our inquiry form. We are looking forward to your inquiry.