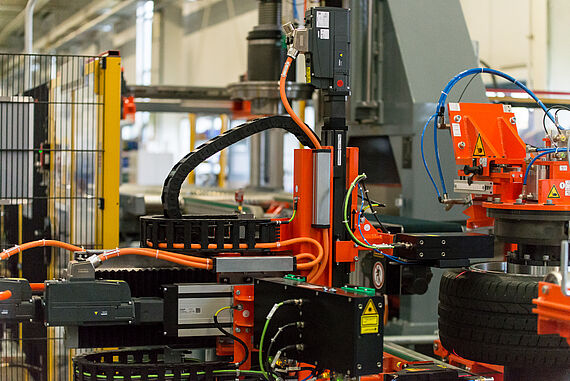

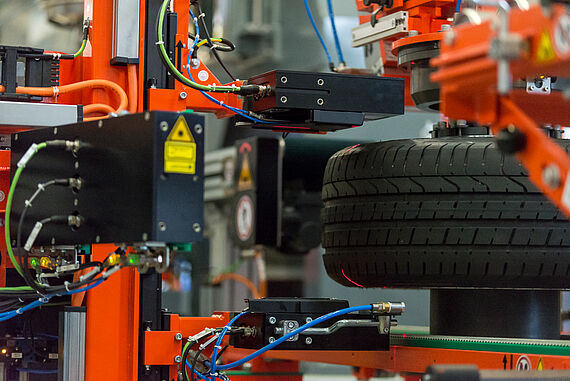

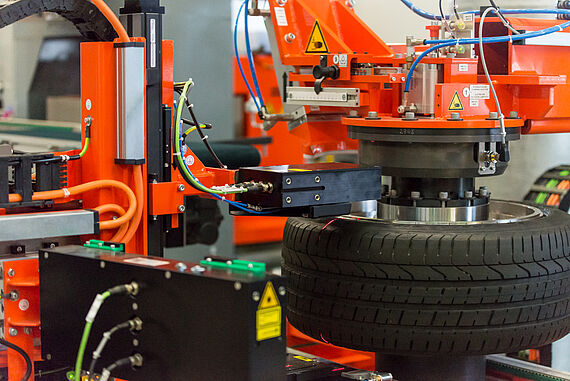

Sheet of Light Laser

Tire geometry system for non-contact radial runout detection

Our laser measuring system for tire geometry, type GEO-SLS delivers high precision and excellent measuring results due to the integrated Sheet of Light Laser sensors. Both axial andradial runout are measured without contact.

The geometry measurement is carried out by the fully automatically positioned Sheet of Light Laser sensors. They are arranged individually for each tire size to be inspected. The positions are automatically stored in the inspection plan.

Value detection

The following values can be determined with our laser measuring system:

- Radial runout (RR)

- Axial runout (AR)

- 1st - 10th harmonic RR (1st – 10th HRR)

- 1st - 10th harmonic AR (1st – 10th HAR)

- Tire side fluctuations

- Bulges

- Constrictions

- TDip

- Spot

Special technical features

The GEO-SLS laser measuring system for tire geometry from Hofmann is characterized by the following technical features:

- non-contact Sheet of Light Laser Sensors

- all components are reliable and easy to maintain

- excellent measuring results for all Hofmann tire uniformity measuring machines, type RGM-E and for all Hofmann tire balancing machines, type ARS

- RRO sensor for the whole range from 400 mm (passenger car tires) and 600 mm (light truck tires)

- fully automatic engagement of the sensors

- excellent and reliable measurement results independent of the rubber composition of the tire

- Repetitive accuracy (standard deviation with inflated tire): 0.05 mm

Your competent contact for Tire Testing Machines

Tire Industry

Michael Hierse

+49 6242 904-160

tiretesting@hofmannmaschinen.com

If our offer of our Tire geometry system has convinced you, please use our inquiry form. We are looking forward to your inquiry.